Due to recent weather patterns which have prompted high winds and heavy rain in certain regions, OFTEC would like to remind technicians when carrying out appliance servicing and storage tank maintenance to also assess the integrity of a fuel storage tank especially regarding its location, taking in consideration the environmental risks due to exposure to ultraviolet rays, flooding and high winds.

With adverse weather due to climate changes, the importance to undertake a safety check and a risk assessment of fuel storage tanks is necessary and by using OFTEC TI/133D or TI/133ND forms could help mitigate risk when a fuel storage tank is situated in an area especially susceptible to flooding and/or exposure to high winds. This may very well include areas that have previously not suffered from flooding or high winds, with sudden storms occurring more frequently in recent years the risks associated with the proper placement of tanks have only increased.

Improper positioning of fuel storage tanks can lead to many costs and problems for both technicians and homeowners. Should the tank supporting base fail due to soft or waterlogged ground, be inadequately or incorrectly secured it could blow over in periods of high winds, or in the event of flooding it could float away leading to the escape of fuel because of ruptured pipework causing costly environmental pollution incidents, expensive rectification work, ground remediation and possible large fines. These are just some of the reasons that OFTEC would always recommend using a registered technician to undertake an inspection of new and existing tank locations to reduce risk of potential hazards.

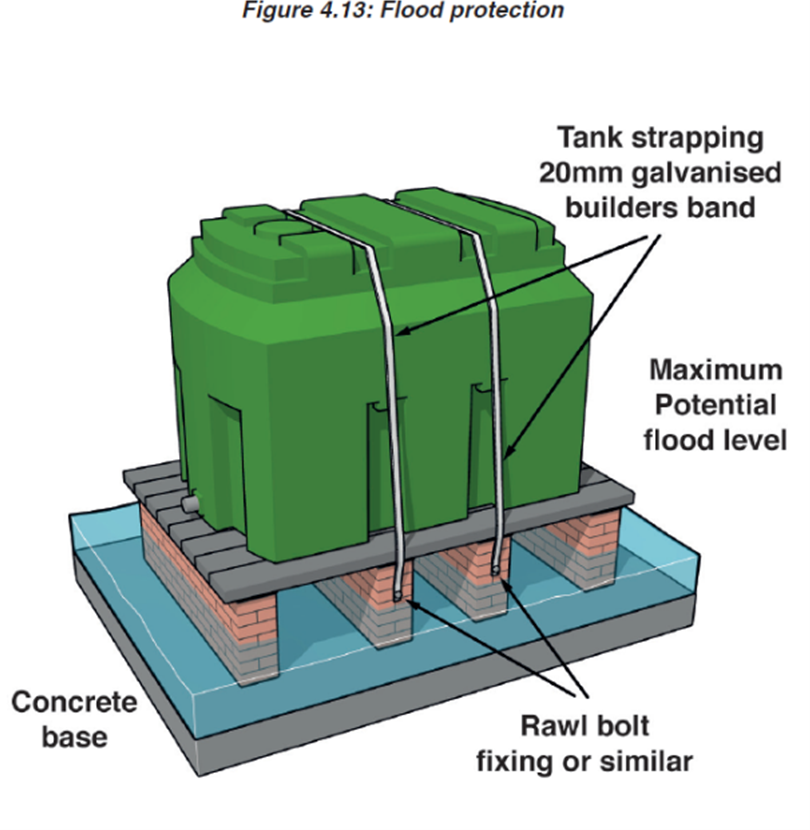

Technicians should only consider tank locations prone to flooding if no alternatives exist. If installing a tank in such an area, you should ensure the following measures have been taken:

- An assessment has been undertaken to mitigate risks.

- The tank should be of the top outlet type with anti-syphon valve installed.

- Raised above the maximum predicted flood level (ensuring safe filling can still be maintained); and

- Restraining the tank. One method that may be suitable is to use 20mm galvanised builders’ steel band, evenly spaced over the tank and securely affixed to the tanks base. The band should not be overly tightened against the surface of the tank as this will restrict the tanks natural movement. Before proceeding with a tank restraint, the tank manufacturer should be consulted to establish suitable anchor and stress points.

Tank support

If a fuel storage tank is not adequately supported, it could lead to safety concerns, the eventual failure of the tank and even a fuel spill. The base needs to provide continual structural support of the imposed load, even though ground conditions may vary from season to season.

The base should be:

- Adequate for the weight of the tank and its contents (1000 litres of fuel weighs just under a one metric tonne).

- Constructed on top of a compacted hardcore sub-base (minimum thickness based on the type of base being installed)

- Non-combustible, level and imperforate (without holes or voids).

- Constructed of cast/poured concrete, paving slabs or stonework of the correct thickness.

- Large enough to extend a minimum 300mm beyond all sides of the tank.